Crusher Does Tertiary

The Complete Guide to Primary Crushing,

2023年2月28日 The main difference between secondary crushing and tertiary crushing is the size of the output material Secondary crushing produces a smaller, more uniform product size that can be fed into the tertiary crushers, 2015年7月25日 Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher Within a secondary and tertiary crushing circuit there are three main types of machinery, CONVEYORS, CRUSHERS, and Secondary Tertiary Crushing Circuits2021年4月12日 Types of Tertiary and Quaternary Crushers For fine sizing, tertiary or even quaternary crushing stages may follow the primary and secondary stages Cone Crushers are the most common types of tertiary and quaternary Downstream Crushing Options for Secondary, What is Tertiary Impact Crusher? A tertiary impact crusher is a type of crusher used in the tertiary stage of crushing and is used to produce cubical shaped aggregates and sand Different Tertiary Impact Crusher MEKA Crushing Screening and 2024年11月7日 The most common type of cone crusher is the Symons cone crusher, which has been designed for use in secondary or tertiary crushing applications The main difference Stages of Rock Crushing: Crushing StationsA tertiary crusher is a machine used in the mining and construction industries for reducing the size of medium to hard materials into finer particles It typically follows primary and secondary What is a tertiary crusher? zenithmineral

Crushers: 5 types and their main failures

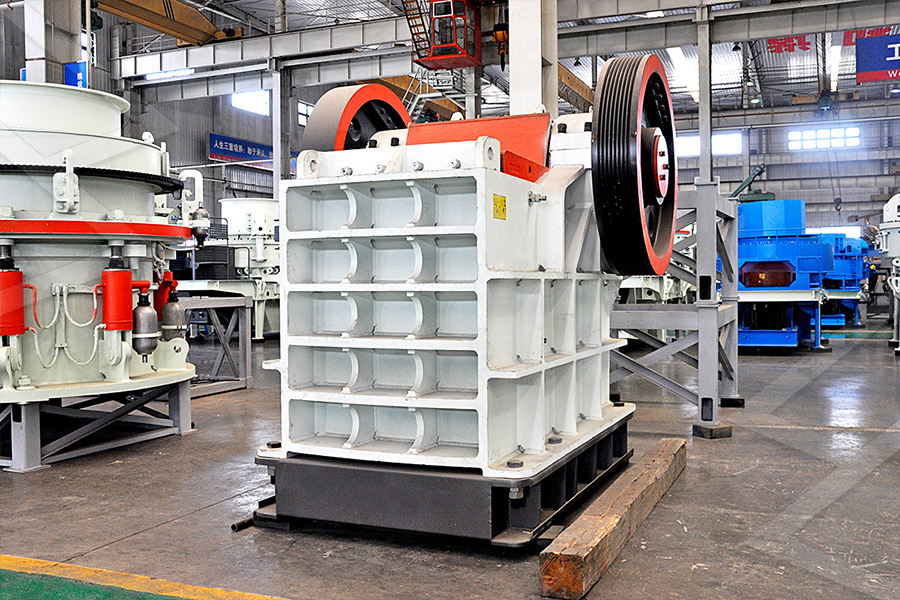

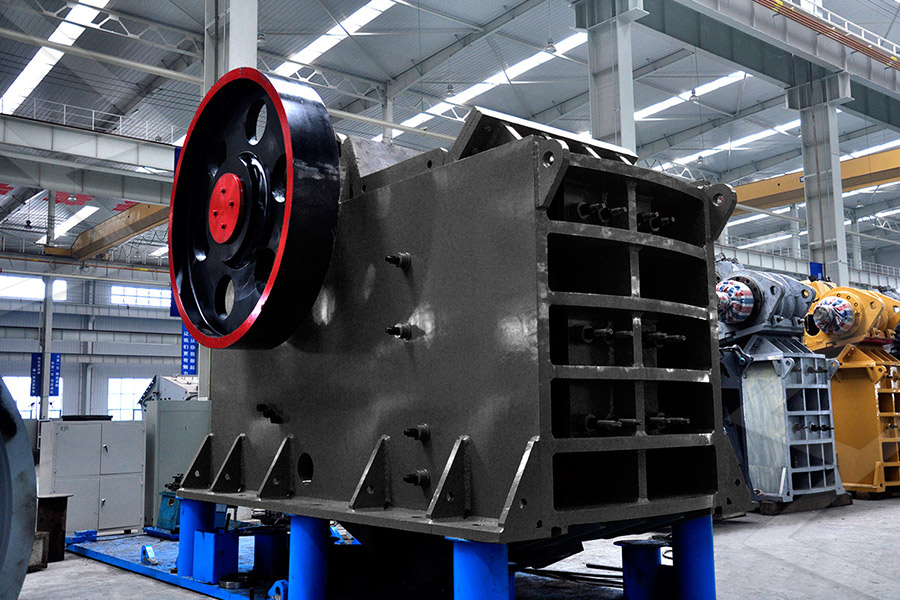

2024年4月19日 The crushing process is divided into three main stages: primary, secondary, and tertiary In the primary stage, heavy machinery is used to reduce the size of the material coming from the mines (blocks from 1000 to 500 mm 2024年4月19日 The crushing process is divided into three main stages: primary, secondary, and tertiary In the primary stage, heavy machinery is used to reduce the size of the material coming from the mines (blocks from 1000 to 500 mm Crushers: 5 types and their main failures2021年4月12日 Tertiary and Quaternary Crushing The tertiary and quaternary crushing stages are used for the final sizing of products Since quality requirements for final products can be stringent, it is important to include a Downstream Crushing Options for Secondary, 2015年7月25日 The fines will be taken out of the circuit Once the secondary has finished with the ore it will be reclassified by a second set of screens with the oversize going to the tertiary crusher The discharge of the tertiary is Secondary Tertiary Crushing Circuits2024年7月17日 The compound crusher, a doublerotor primary impact crusher, is a new type of fine crushing and coarse grinding product launched by FTM Machinery Materials entering the Types of Crushers: Choosing the Right One for Each Stage2019年10月21日 Finally, the tertiary crusher has a typical 3:1 ratio reduction from 150 to 50 millimetres Again, a screen located before the tertiary crusher can be beneficialTwo vs threestage crushing Australian Mining

.jpg)

What Is A Jaw Crusher MEKA Crushing Screening and

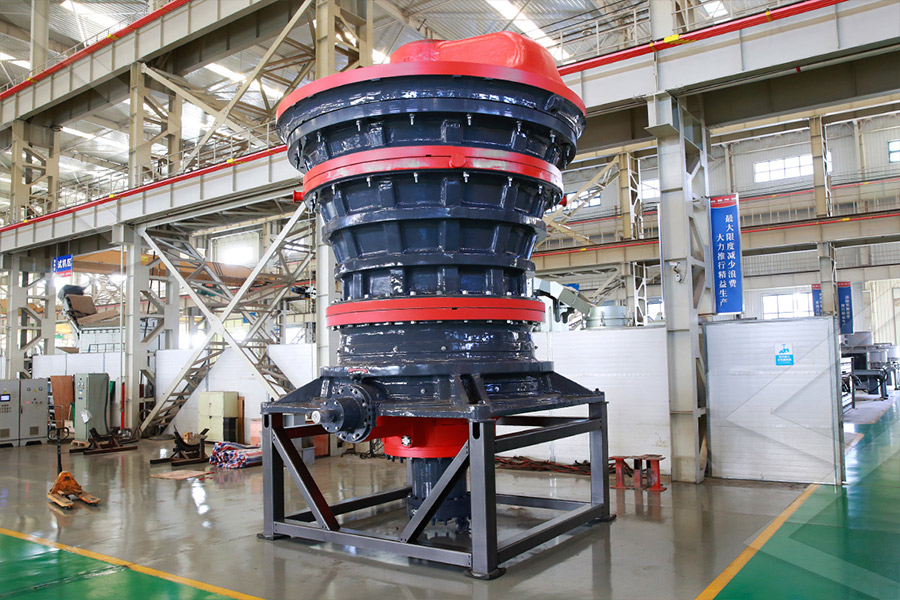

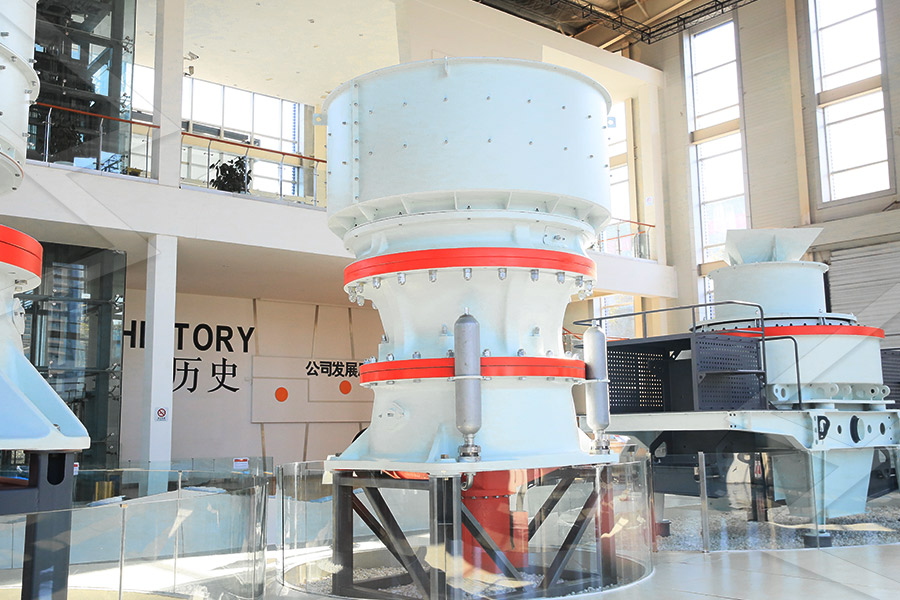

Tertiary Crushing This is the third stage of crushing The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12 mm We call 2015年9月10日 crusher Tertiary crushing is usually performed using cone crushers or other types of impactor crushers Oversize material from the top deck of the sizing screen is fed to 11192 Crushed Stone Processing and Pulverized 2018年9月10日 Selecting an appropriate crusher, or indeed any piece of processing equipment, is important in every quarry operation Cone crushers are used in secondary and tertiary Understanding the Different Types of Crushers AggNet2023年7月20日 in high performance crusher In addition, whenever tertiary crushing stage can be avoided, the capital costs and need for energy drop notably Durable wear parts and Nordberg® NP Series™ Horizontal shaft impact (HSI) The Trio® TC Series cone crusher is the latest iteration of the liveshaft crusher design This design has been proven to perform in heavyduty secondary and tertiary crushing applications Trio® TC Series Cone Crusher Weir Weir Group2024年11月7日 The most common type of cone crusher is the Symons cone crusher, which has been designed for use in secondary or tertiary crushing applications The main difference Stages of Rock Crushing: Crushing Stations

.jpg)

Secondary or Tertiary Crusher Superior Industries

2 天之前 The Patriot Cone Crusher is a reliable and valuable choice for secondary or tertiary applications It comes with a standard 2yr / 6,000hr warranty and topquality components Its proven design simplifies For businesses that process large pieces of raw material, cone crushers are used as a secondary or tertiary crusher The Benefits of Cone Crushers Cone crushers offer a bunch of benefits that are helpful for practically every industry that A Detailed Overview of Cone Crushers and What Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp Cone Crushers (Parts of a Cone Crusher) Explained saVRee2024年5月15日 The Trio® TC Series cone crusher is the latest iteration of the liveshaft cone crusher This design has been proven to perform in heavyduty secondary and tertiary ESCO® Wear Parts and Liners for Trio® Crushers Weir2010年8月1日 In open circuit grinding, HPGR provides for a high throughput and low energy operation in either a tertiary crushing or pregrinding stage, with the facility to replace Flowsheet considerations for optimal use of high pressure 2023年2月28日 The primary crusher is used to reduce the size of the initial rocks, while the secondary crusher further breaks down the smaller pieces into finer materials Purpose and Primary vs Secondary Crushers: Understanding the

Types of Rock Crushers Quarry Crushing Equipment Kemper

4 天之前 3 Tertiary/Quaternary/Final Reduction Crushing The goal of the tertiary (third), quaternary (fourth) or final reduction stage of the crushing process is to size and shape rock or 2025年5月10日 A cone crusher can crush a variety of rocks, from medium to hard The way a cone crusher operates is similar to how a gyratory crusher does, but in a cone crusher the Choosing the Right Crusher Buying Guides DirectIndustryIt is often used as a secondary or tertiary crusher It is best for crushing material 200 mm and less Advantages of a cone crusher include high productivity and low operating costs However, a cone crusher does not generate evenly sized Buyer’s Guide: Crushers Equipment ContractingAll crusher types with 100+ years of experience Metso crushers are fit for aggregates production, construction material recycling and mining operations tertiary, and quaternary crushing stages Sometimes, however, the grain size Crushers All crusher types for your reduction So what does tertiary crusher mean? Tertiary means tertiary Primary crushing reduces stones by only coarse crushing If necessary, a secondary or secondary crushing is done to reduce the size of the stone even more In the Tertiary Mobile Crusher Price Mobile Crusher For SaleThe roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed Crusher an overview ScienceDirect Topics

.jpg)

Tertiary Impact Crushers Pyramids Machine

The Tertiary Impact Crushers offered by Pyramids are specifically designed for crushing materials of medium and low hardness, commonly at the tertiary stage Features and Benefits of the 2016年7月14日 The most common HPGR based circuit involves feeding primary crusher product to a secondary crushing circuit with of cone crushers in closed circuit with screens, followed by HPGR 911MetallurgistImpact vs Hammer Mill Crusher Courtesy of Aimix Group Tertiary crushing equipment and beyond Sometimes you might need to continue to reduce the size of your crushed material, What is a Crusher? Machinery PartnerA tertiary crusher is a crushing machine used in the third stage of the material crushing process After the material passes through the primary crusher and secondary crusher, the tertiary Tertiary Crusher Problems and Best Eon Solution2024年10月14日 In addition to the fixed cone crushers, many cone crusher models are also available as mobile versions This type of cone crusher can be combined with the jaw crusher, 4 Types of Cone Crushers: What Are They and How to SelectTertiary crusher: 10:1 Therefore, if a 3 mm crusher product is required, maximum feed size to the secondary crusher would be 240 mm Thus, the feed to the primary crusher should not exceed AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Crushers: 5 types and their main failures

2024年4月19日 The crushing process is divided into three main stages: primary, secondary, and tertiary In the primary stage, heavy machinery is used to reduce the size of the material coming from the mines (blocks from 1000 to 500 mm 2021年4月12日 Tertiary and Quaternary Crushing The tertiary and quaternary crushing stages are used for the final sizing of products Since quality requirements for final products can be stringent, it is important to include a Downstream Crushing Options for Secondary, 2015年7月25日 The fines will be taken out of the circuit Once the secondary has finished with the ore it will be reclassified by a second set of screens with the oversize going to the tertiary crusher The discharge of the tertiary is Secondary Tertiary Crushing Circuits2024年7月17日 The compound crusher, a doublerotor primary impact crusher, is a new type of fine crushing and coarse grinding product launched by FTM Machinery Materials entering the Types of Crushers: Choosing the Right One for Each Stage2019年10月21日 Finally, the tertiary crusher has a typical 3:1 ratio reduction from 150 to 50 millimetres Again, a screen located before the tertiary crusher can be beneficialTwo vs threestage crushing Australian MiningTertiary Crushing This is the third stage of crushing The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12 mm We call What Is A Jaw Crusher MEKA Crushing Screening and

.jpg)

11192 Crushed Stone Processing and Pulverized

2015年9月10日 crusher Tertiary crushing is usually performed using cone crushers or other types of impactor crushers Oversize material from the top deck of the sizing screen is fed to 2018年9月10日 Selecting an appropriate crusher, or indeed any piece of processing equipment, is important in every quarry operation Cone crushers are used in secondary and tertiary Understanding the Different Types of Crushers AggNet2023年7月20日 in high performance crusher In addition, whenever tertiary crushing stage can be avoided, the capital costs and need for energy drop notably Durable wear parts and Nordberg® NP Series™ Horizontal shaft impact (HSI) The Trio® TC Series cone crusher is the latest iteration of the liveshaft crusher design This design has been proven to perform in heavyduty secondary and tertiary crushing applications Trio® TC Series Cone Crusher Weir Weir Group